Industrial

Elnabbe can conduct the ccs projects in the industrial sector in a cooperation with our partners

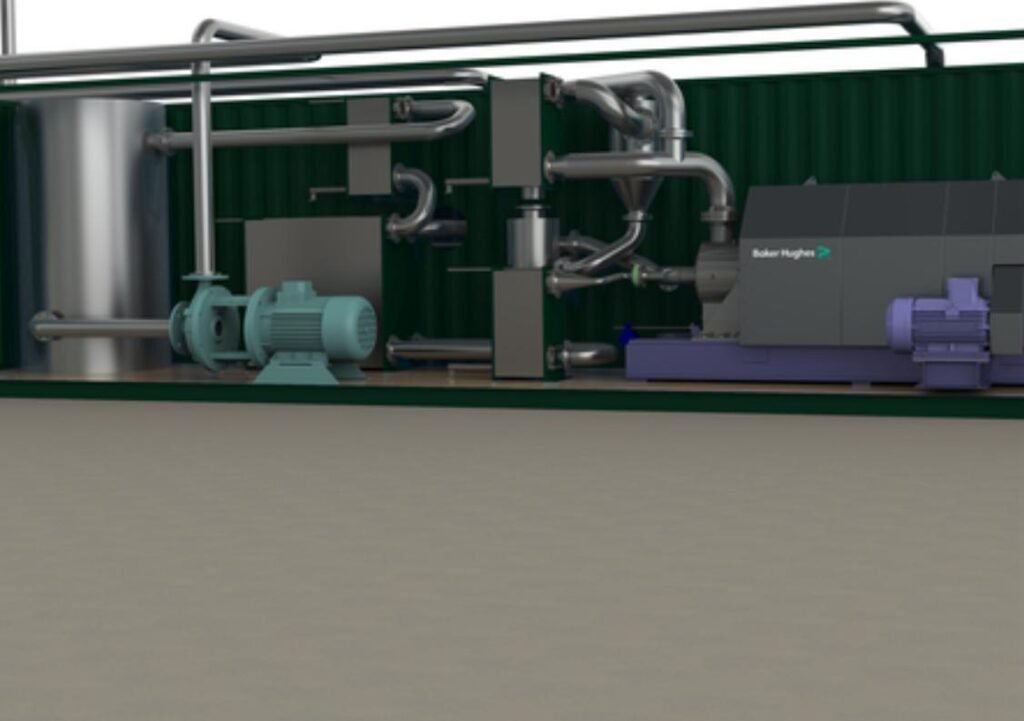

Carbon Capture and Storage (CCS) projects in the industrial sector involve capturing CO₂ emissions from industrial processes, transporting the captured CO₂, and storing it securely in geological formations or utilizing it for other purposes. Industrial CCS is critical for decarbonizing hard-to-abate sectors such as cement, steel, chemicals, and refining. Below are the key processes involved in industrial CCS projects:

Elnabbe con do the following projects by the cooperation with our partners

1- Project Planning and Feasibility Assessment

- Identify Emission Sources: Determine the major sources of CO₂ emissions within the industrial facility (e.g., flue gases, process emissions).

- Feasibility Study: Assess the technical, economic, and regulatory feasibility of implementing CCS.

- Site Selection: Identify suitable storage sites (e.g., depleted oil and gas fields, saline aquifers) or utilization opportunities nearby.

2-CO₂ Capture

- Capture Technologies: Select the appropriate capture technology based on the industrial process and CO₂ concentration:

- Post-Combustion Capture: Use solvents (e.g., amine-based) to separate CO₂ from flue gases after combustion.

- Pre-Combustion Capture: Convert fossil fuels into syngas (CO + H₂), separate CO₂, and burn the remaining hydrogen.

- Oxy-Fuel Combustion: Burn fuels in pure oxygen to produce a concentrated CO₂ stream.

- Direct Air Capture (DAC): Capture CO₂ directly from the atmosphere (less common in industrial CCS).

- Pilot Testing: Conduct pilot projects to validate the chosen capture technology.

3-CO₂ Transportation

- Pipeline Networks: Transport CO₂ via pipelines to storage sites or utilization facilities. Repurpose existing infrastructure where possible.

- Shipping: Use ships for transporting CO₂ to offshore storage sites or distant utilization hubs.

- Safety Measures: Implement real-time monitoring and leak detection systems during transportation.

4-CO₂ Storage

- Geological Storage: Inject CO₂ into deep geological formations such as depleted oil and gas reservoirs or saline aquifers.

- Storage Site Characterization: Conduct detailed geological and geophysical surveys to ensure the site is suitable for long-term storage.

- Injection Process: Drill injection wells and inject CO₂ at high pressure, ensuring it is trapped by caprock and other mechanisms.

5-CO₂ Utilization (Optional)

- Enhanced Oil Recovery (EOR): Inject CO₂ into oil fields to enhance oil production while storing CO₂.

- Chemical Production: Use CO₂ as a feedstock for producing chemicals (e.g., methanol, urea).

- Building Materials: Convert CO₂ into aggregates for construction materials (e.g., concrete).

- Fuels and Plastics: Synthesize synthetic fuels or polymers using CO₂.

6- Monitoring, Verification, and Reporting (MVR)

- Seismic Monitoring: Track the movement of CO₂ within the storage site using 4D seismic surveys.

- Well Monitoring: Monitor injection wells and nearby observation wells for pressure, temperature, and CO₂ concentration.

- Surface Monitoring: Detect potential leaks using soil gas surveys, atmospheric monitoring, and satellite imagery.

- Data Reporting: Regularly report monitoring data to regulators and stakeholders to ensure compliance and transparency.

7-Risk Management and Mitigation

- Leak Prevention: Design wells and storage sites to prevent CO₂ leakage.

- Contingency Plans: Develop emergency response plans for potential leaks or other incidents.

- Long-Term Liability Management: Establish protocols for long-term monitoring and liability transfer after site closure.

8-Regulatory and Permitting Processes

- Obtain necessary permits from regulatory authorities for capture, transportation, injection, and monitoring.

- Comply with national and international standards (e.g., ISO 27914 for geological storage).

9-Project Closure and Post-Closure Monitoring

- Site Closure: Properly seal and abandon injection wells after the project ends.

- Long-Term Monitoring: Continue monitoring the site for decades to ensure the CO₂ remains securely stored.

- Liability Transfer: Transfer responsibility for the site to a designated authority after demonstrating long-term stability.

10-Integration with Industrial Processes

- Cement Industry: Capture CO₂ from kiln emissions and utilize it in curing processes or mineral carbonation.

- Steel Industry: Capture CO₂ from blast furnace gases and integrate with hydrogen-based steelmaking.

- Chemicals and Refining: Capture CO₂ from process emissions and use it as a feedstock for chemical synthesis.

- Waste-to-Energy: Capture CO₂ from waste incineration and store or utilize it.

11-Economic and Policy Incentives

- Leverage carbon pricing, tax credits, or subsidies to improve project economics.

Participate in carbon markets or emission trading systems (ETS) to monetize CO₂ reductions