CCS Projects

Geological Carbon Capture and Storage (CCS) is a process that involves capturing carbon dioxide (CO₂) emissions from industrial sources, transporting them to a storage site, and injecting them into deep geological formations for long-term storage. In the oil and gas industry, CCS is often integrated with Enhanced Oil Recovery (EOR) to improve oil production while reducing CO₂ emissions. Below are the key processes involved in a geological CCS project:

Elnabbe can conduct the following projects by the cooperation with our partners

1- Site Selection and Characterization

- Identify Suitable Storage Sites: Evaluate geological formations (e.g., depleted oil and gas reservoirs, saline aquifers) for their capacity, infectivity, and containment properties.

- Geological and Geophysical Surveys: Conduct seismic surveys, well logging, and core sampling to assess the structure, porosity, and permeability of the storage site.

Risk Assessment: Evaluate potential risks such as leakage, induced seismicity, and environmental impacts

2-CO₂ Capture

- Capture Technologies: Use technologies like amine scrubbing, membrane separation, or cryogenic distillation to capture CO₂ from industrial sources (e.g., power plants, refineries,

3-CO₂ Transportation

- Pipeline Networks: Transport CO₂ via pipelines to the storage site. Existing oil and gas infrastructure can often be repurposed for this purpose.

- Shipping: In some cases, CO₂ is transported via ships to offshore storage sites.

- Monitoring During Transport: Ensure safe and leak-free transportation through real-time monitoring.

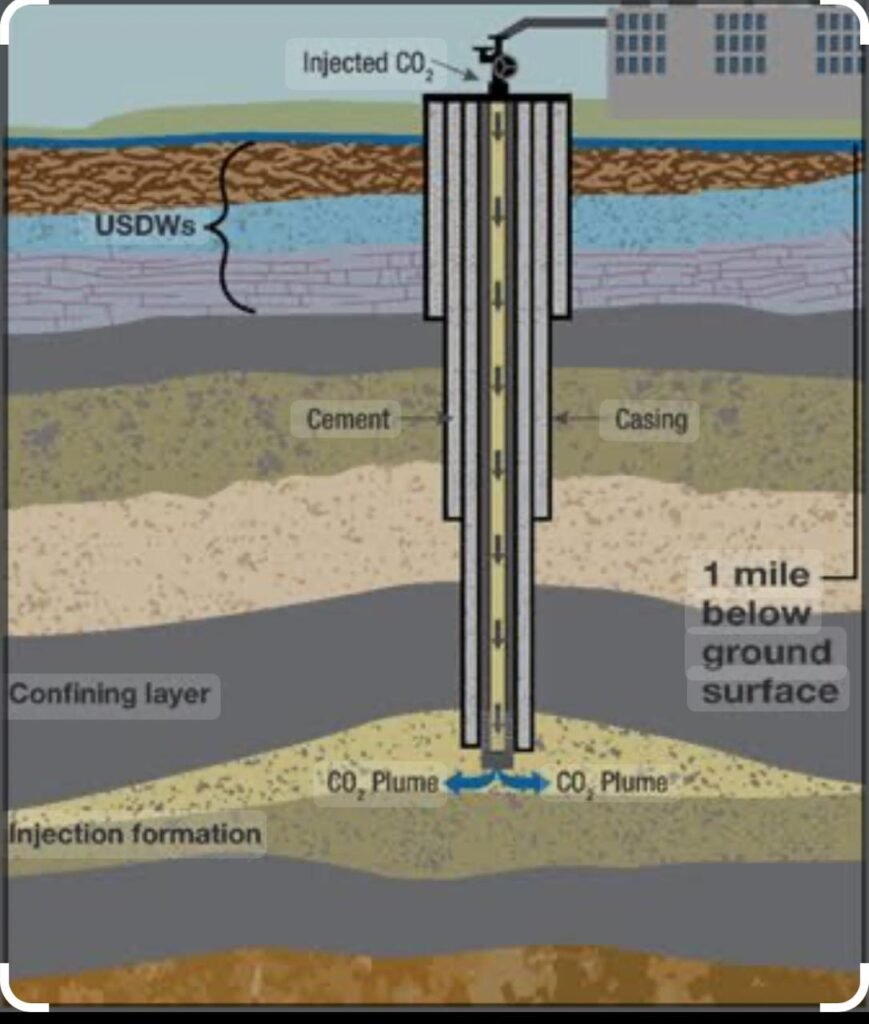

4-CO₂ Injection

- Injection Wells: Drill and complete wells specifically designed for CO₂ injection into the target geological formation.

- Injection Process: Inject CO₂ at high pressure into the formation, where it is trapped by caprock (impermeable rock layers) and other mechanisms.

- Enhanced Oil Recovery (EOR): In oil fields, inject CO₂ to enhance oil recovery while simultaneously storing CO₂.

5- Storage and Injection Mechanisms

- Structural Trapping: CO₂ is trapped beneath impermeable caprock.

- Residual Trapping: CO₂ is trapped in the pore spaces of the rock.

- Dissolution Trapping: CO₂ dissolves into the formation water.

- Mineral Trapping: CO₂ reacts with minerals to form stable carbonate compounds over time.

6- Monitoring, Verification, and Reporting (MVR)

- Seismic Monitoring: Use 4D seismic surveys to track the movement of CO₂ within the reservoir.

- Well Monitoring: Monitor injection wells and nearby observation wells for pressure, temperature, and CO₂ concentration.

- Surface Monitoring: Detect potential leaks using soil gas surveys, atmospheric monitoring, and satellite imagery.

- Data Reporting: Regularly report monitoring data to regulators and stakeholders to ensure compliance and transparency.

7- Risk Management and Mitigation

- Leak Prevention: Design wells and storage sites to prevent CO₂ leakage.

- Contingency Plans: Develop plans to address potential leaks or other emergencies.

- Long-Term Liability Management: Establish protocols for long-term monitoring and liability transfer after site closure.

8- Regulatory and Permitting Processes

- Obtain necessary permits from regulatory authorities for site selection, drilling, injection, and monitoring.

- Comply with national and international standards (e.g., ISO 27914 for geological storage).

9- Project Closure and Post-Closure Monitoring

- Site Closure: Properly seal and abandon injection wells after the project ends.

- Long-Term Monitoring: Continue monitoring the site for decades to ensure the CO₂ remains securely stored.

10- Integration with Oil and Gas Operations

- Synergy with EOR: Use CO₂ for enhanced oil recovery to offset project costs and improve oil production.

- Utilization of Existing Infrastructure: Leverage existing wells, pipelines, and facilities to reduce costs.